Product Description, Technical Advantages, and Applications

A dismantling joint is an essential pipeline component designed to facilitate the installation, removal, and maintenance of valves, pumps, and other pipeline equipment. By providing axial adjustment and structural support, dismantling joints allow components to be assembled or dismantled without modifying adjacent pipe sections, significantly improving installation efficiency and long-term maintainability.

Dismantling joints are widely used in water supply systems, wastewater treatment plants, industrial pipelines, power stations, and oil and gas facilities where reliable sealing and frequent maintenance are required.

What Is a Dismantling Joint?

A dismantling joint is a mechanical pipe fitting installed between flanged pipeline components. Its primary function is to provide sufficient axial tolerance so that connected equipment can be easily installed, removed, or replaced.

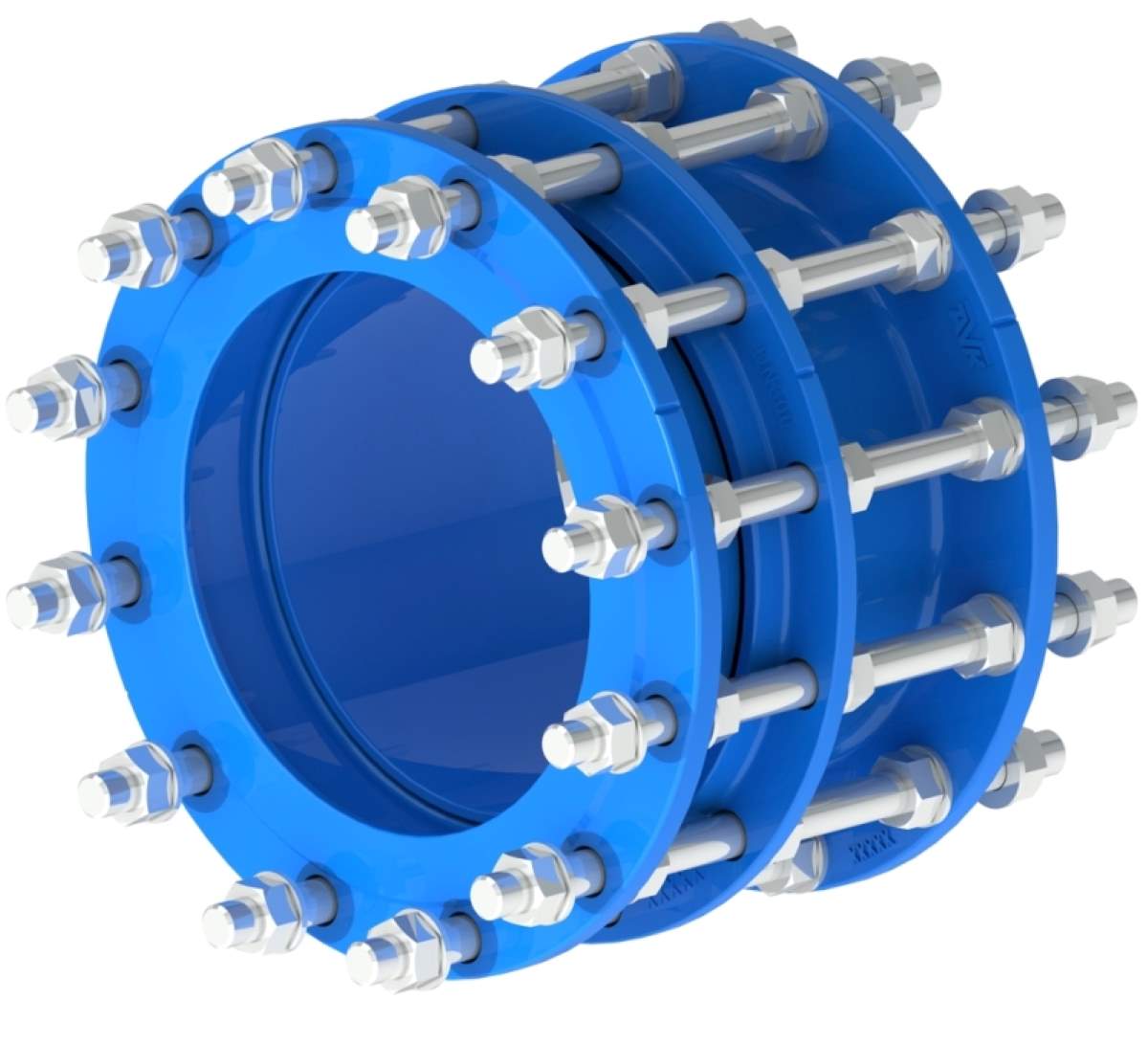

A standard dismantling joint typically consists of:

- A joint body that connects two pipeline sections

- A dismantling flange adaptor that ensures a secure and leak-tight flange connection

- Tie rods that absorb axial thrust forces generated by internal pressure

Together, these components form a rigid yet adjustable connection that remains stable during operation while allowing flexibility during installation and maintenance.

Key Technical Advantages of Dismantling Joints

Axial Adjustment for Easy Valve and Pump Installation

One of the most important advantages of a dismantling joint is its axial adjustment capability. This allows installers to compensate for small dimensional deviations between pipelines and equipment flanges, reducing installation stress and eliminating the need for pipe cutting or forced alignment.

This feature is particularly valuable in valve installation and replacement projects.

Secure Sealing Performance Under Operating Pressure

The dismantling flange adaptor is designed to provide reliable sealing under high internal pressure. Even load distribution on the gasket surface minimizes the risk of leakage, ensuring safe and stable operation in both water and industrial pipeline systems.

At the same time, the joint can be loosened and reassembled without damaging the sealing surfaces, making it suitable for repeated maintenance operations.

Effective Control of Axial Thrust Forces

Tie rods are a critical structural element of dismantling joints. They restrain axial movement and absorb pressure-induced thrust forces, protecting valves, pumps, and other connected equipment from excessive mechanical loads. This improves overall pipeline safety and reduces the risk of flange failure.

Reduced Maintenance Time and Operating Costs

By allowing direct removal of inline equipment, dismantling joints significantly shorten maintenance time. This leads to lower labor costs, reduced downtime, and improved system availability throughout the pipeline’s service life.

Types of Dismantling Joints

To meet different installation requirements, dismantling joints are available in several configurations:

- Single Flange Dismantling Joint – suitable for simple pipeline connections

- Double Flange Dismantling Joint – provides greater axial adjustment and installation flexibility

- Telescopic Dismantling Joint – designed to accommodate thermal expansion and contraction

Selecting the correct type depends on pipeline layout, operating conditions, and maintenance frequency.

Materials Used in Dismantling Joint Manufacturing

Dismantling joints can be manufactured from different materials to suit specific service conditions:

- Carbon Steel Dismantling Joints for high-strength industrial applications

- Stainless Steel Dismantling Joints for corrosive or hygienic environments

- Ductile Iron Dismantling Joints commonly used in water supply and wastewater systems

- Composite Dismantling Joints for lightweight or special-purpose applications

Material selection directly affects corrosion resistance, pressure capacity, and service life.

Typical Applications of Dismantling Joints

Dismantling joints are commonly used in:

- Water distribution and transmission pipelines

- Wastewater treatment plants

- Pump stations and valve chambers

- Power generation facilities

- Oil, gas, and chemical processing pipelines

Their ability to simplify maintenance makes them especially valuable in large-diameter or high-pressure pipeline systems.

Standards, Quality Control, and Long-Term Reliability

High-quality dismantling joints are manufactured in accordance with international standards such as ISO quality management systems and material standards including EN and ASTM. Pressure testing and dimensional inspections are typically carried out to ensure reliable performance under operating conditions.

Well-manufactured dismantling joints offer improved durability, enhanced safety, and reduced maintenance costs, making them a cost-effective solution for long-term pipeline operation.

Post time: Jan-09-2026