Products

Double Eccentric Butterfly Valve

Brief description:

- DOUBLE ECCENTRIC BUTTERFLY VALVE

- With EN1074-1 & EN1074-2 type approval certification, for use with drinking water, WRAS approved

- PRESSURE RATING: PN10, PN16, PN25, PN40

- SIZE RANGE: DN200 ~ DN4000

- SEAT MATERIAL: EPDM/NBR/VITON/SILICONE/METAL

Product description

Valve design to EN 593, BS5155, DIN3354

Flange to EN 1092, ASME B16.5, ASME B16.1, AWWA C207

Face to face length to EN 558-1 / ISO 5752 series 14 or series 13

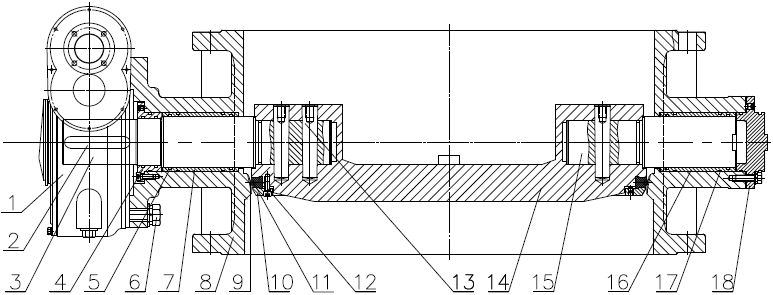

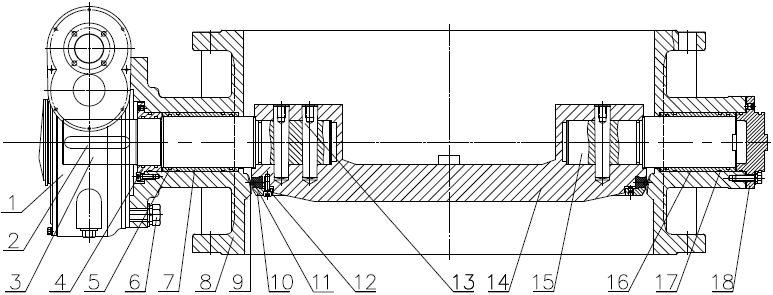

Product detail

- Stainless steel weld and finished body seat ensures a corrosion and wear resistant seat face.

- Streamlined low profiled disc design ensures the higher strength and the lower flow resistance.

- By designing a sealing gasket at the connection between the bearing and the valve disc, installing a double O-ring on the bearing, and closing the valve disc hole to avoid corrosion from the medium used.

- Disc to shaft connection by means of taper pin or key(optional).

- Bronze or stainless steel lined PTFE self-lubricating bearings can reduce shaft friction and prevent axial movement.

- Suitable for full vacuum service conditions. Anti-blow out shaft design.

- T profiled resilient seal ring is secured on the disc by a retainer ring and bolts, and ensures reliable sealing performance in double direction.

- Operated with gearbox + handwheel and with ISO 5210 top flange to be coupled with an electric actuator, if required at a later date.

- Valve externally and internally fusion bonded epoxy coated with a thickness of 250micron (different coating/lining is available as special request) and color code RAL5005/5015/5017.

- Suitable for the applications involving throttling service and for applications requiring valve actuation after long periods of inactivity.

Materials of component

| Part No | Description | Material | Part No | Description | Material |

| 1 | Gear housing | Ductile iron,GJS400-15 | 10 | Retainer ring | Stainless steel, 1.4571 |

| 2 | Key | Stainless steel, 420 | 11 | Disc seal ring | Rubber, EPDM |

| 3 | Upper shaft | Duplex SS, 1.4462 | 12 | Screw | Stainless steel,A2-70 |

| 4 | Packing gland | Ductile iron,GJS400-15 | 13 | Taper pin | Stainless steel, 420 |

| 5 | O ring | Rubber, EPDM | 14 | Valve disc | Ductile iron,GJS400-15 |

| 6 | Bolt | Stainless steel,A2-70 | 15 | Lower shaft | Duplex SS, 1.4462 |

| 7 | Shaft bearing | Bronze, QAl9-2 | 16 | Shaft bearing | Bronze, QAl9-2 |

| 8 | Valve body | Ductile iron,GJS400-15 | 17 | O ring | Rubber, EPDM |

| 9 | Body seat | Stainless steel, 316 | 18 | Shaft cover | Ductile iron,GJS400-15 |

Other materials such as carbon steel, st. steel, duplex SS, aluminum bronze are available on request.

Coating: fusion bonded epoxy coating, min. thickness 300 micron

Suitable medium: potable water, sea water, TSE water, low-corrosive liquid etc.

Suitable temperature: 0 ~ 80 ℃

Pressure test to EN12266-1: Leakage rate: Class A (Zero leakage) in both direction

100% testing before delivery

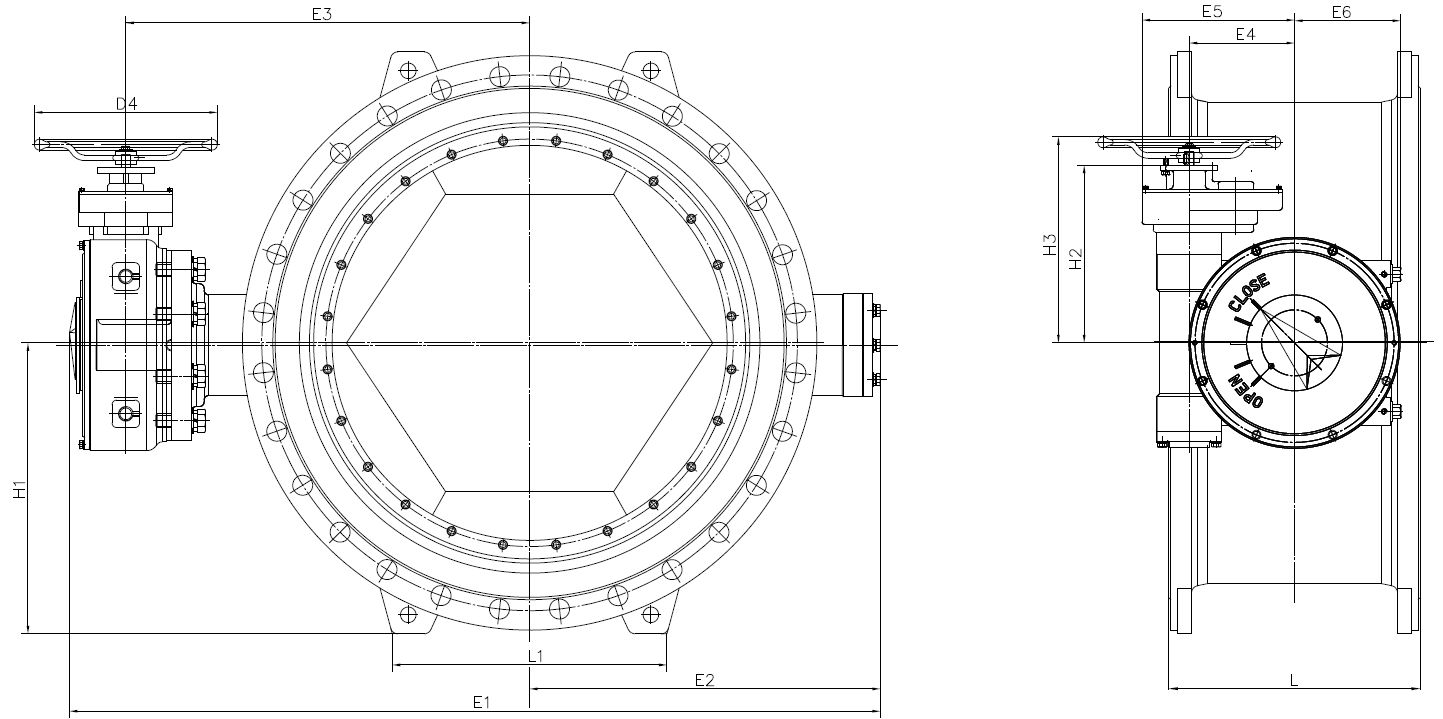

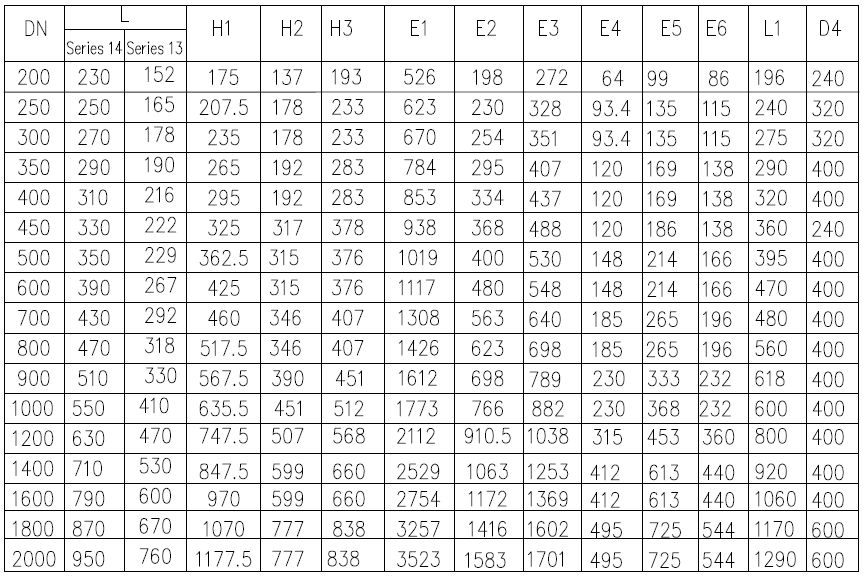

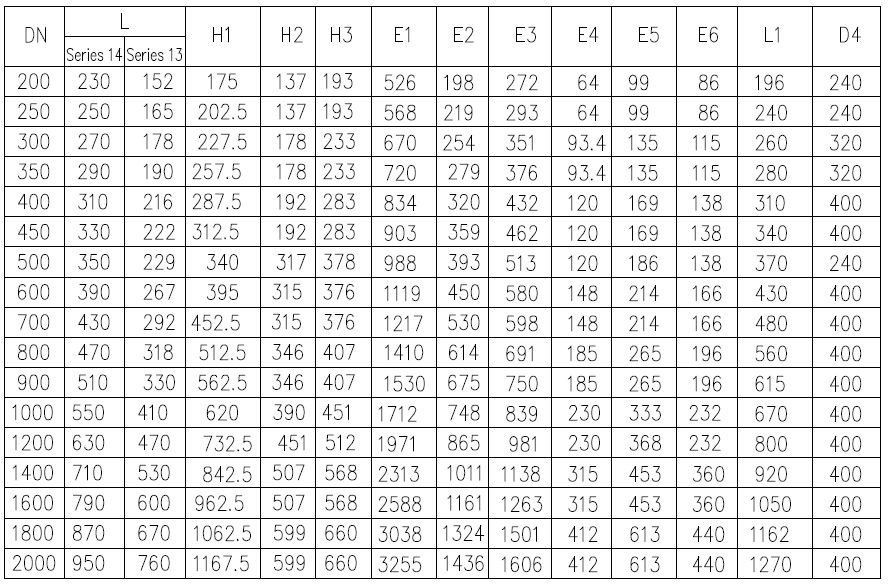

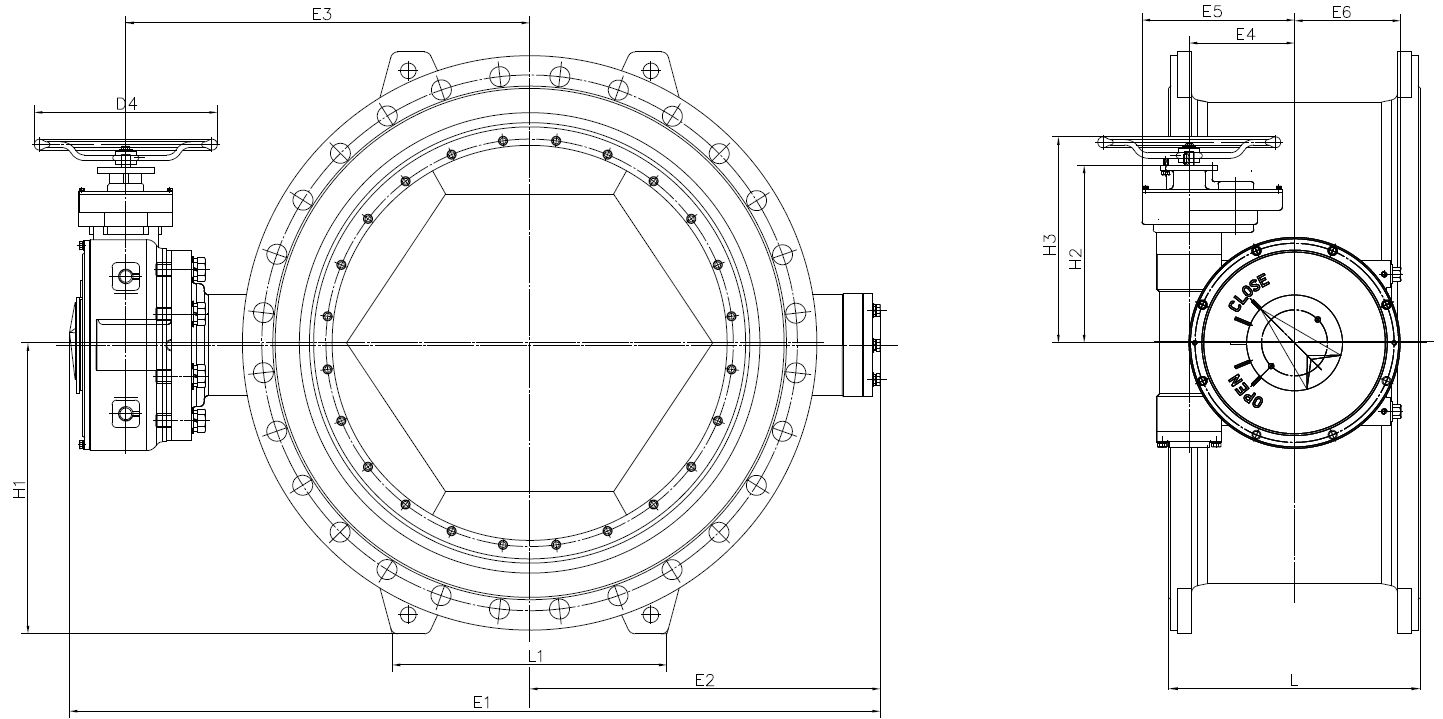

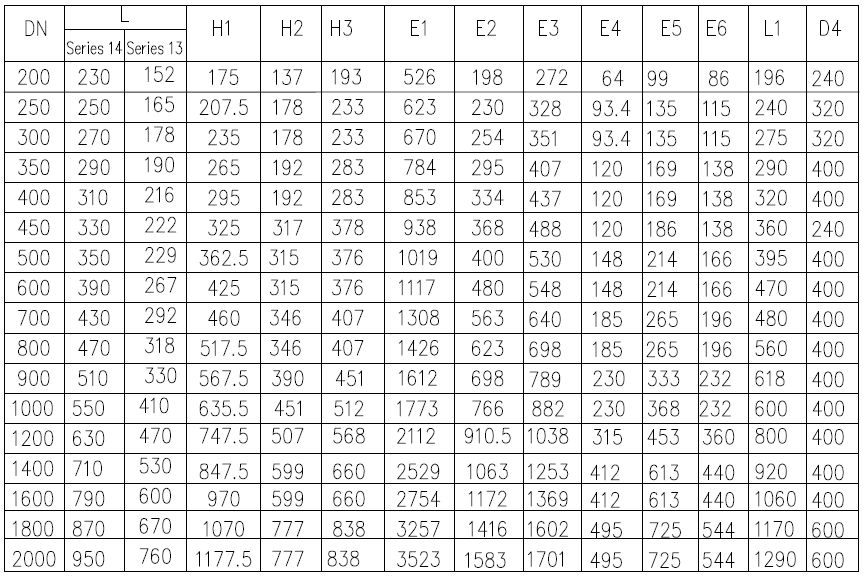

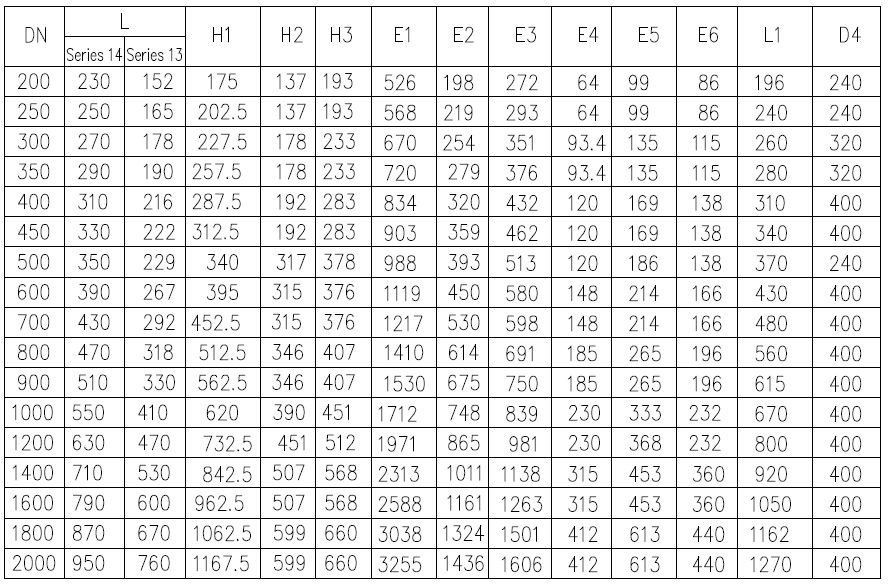

Dimensions

Dimensions/PN10

Dimensions/PN16

Subscribe Now

An unmatched level of quality and serviceWe provide professional customized services for groups and individualsWe optimize our service by nsuring the lowest price.

More products

Write your message here and send it to us