Valves are like the gatekeepers of fluid control systems, playing a vital role in industries such as oil, chemical, and power generation. In power plants, especially under high-temperature and high-pressure (HTHP) conditions, choosing the right valve isn’t just a technical detail—it’s a matter of safety, efficiency, and longevity. When temperatures soar and pressures rise, valve materials are put to the test. Issues like loss of strength, accelerated corrosion, and creep deformation can lead to failures if the wrong material is selected.

So, how do engineers decide which materials to use? Let’s break down the most common metal and non-metal materials used in power plant valves and see how they stand up to extreme environments.

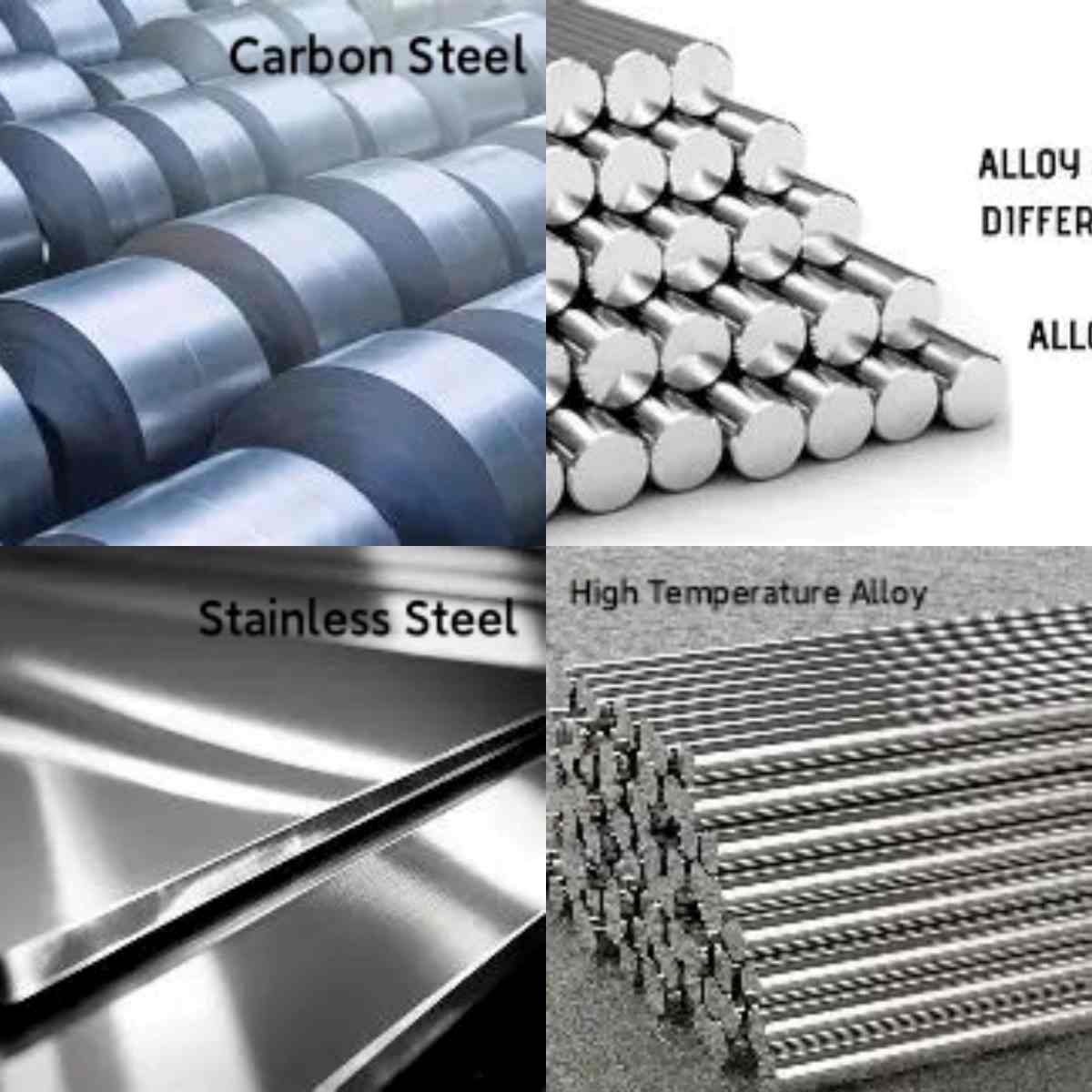

1.Metal Materials for Power Plant Valves

- Carbon Steel

Carbon steel is a popular choice for valve manufacturing thanks to its good mechanical properties and ease of machining. It’s strong, readily available, and cost-effective. Under high temperatures, carbon steel does lose some strength, but within certain temperature limits, it remains reliable.

However, carbon steel has one major drawback: it’s not very corrosion-resistant. In environments where moisture, acids, or other corrosive media are present, carbon steel valves can deteriorate quickly. That makes them better suited for less aggressive service conditions unless coated or treated.

- Alloy Steel

When carbon steel isn’t enough, alloy steel steps in. By adding elements like chromium, molybdenum, and nickel, alloy steels gain improved strength, corrosion resistance, and oxidation resistance. These attributes make them well-suited for HTHP environments, such as those found in steam and process lines in power plants.

The downside? Alloy steels are more expensive and harder to machine than carbon steel. But when reliability under stress is non-negotiable, the extra cost is often justified.

- Stainless Steel

Stainless steel is famous for its corrosion resistance, which comes from a healthy dose of chromium—and sometimes nickel. This makes it ideal for valves exposed to wet, acidic, or oxidative conditions. It also holds up well under high temperatures.

That said, stainless steel isn’t as strong as some alloy steels and can be prone to creep—a slow, permanent deformation under mechanical stress at high temperatures. Even so, its balance of affordability and performance makes it a go-to for many power plant applications.

- High-Temperature Alloys

For the most extreme conditions—think superheaters, turbine bypass systems, or high-pressure steam lines—high-temperature alloys are the top choice. These advanced metals, often nickel or cobalt-based, offer exceptional strength, oxidation resistance, and stability under continuous high heat.

The catch? They’re expensive and difficult to manufacture and machine. But when failure is not an option, these super-alloys provide the ultimate safety net.

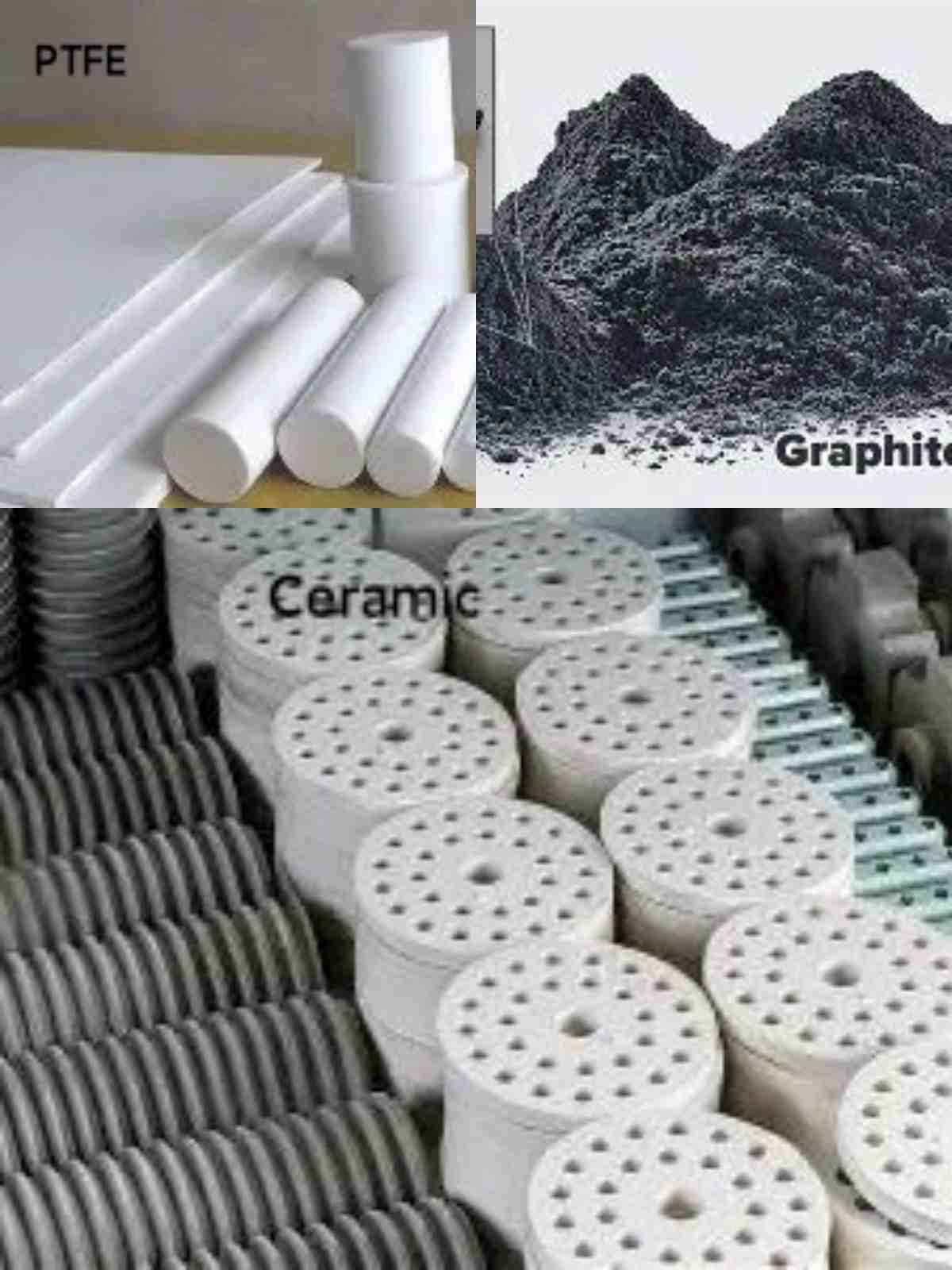

2.Non-Metal Materials for Power Plant Valves

- PTFE (Polytetrafluoroethylene)

PTFE, best known by the brand name Teflon, is a superstar when it comes to sealing. It has an incredibly low coefficient of friction and excellent chemical resistance, making it ideal for valve seats, seals, and linings.

But PTFE has its limits. It doesn’t handle high pressures or temperatures well. Under extreme conditions, it can deform or degrade. That’s why it’s usually reserved for lower-temperature services or as part of a composite sealing solution.

- Graphite

Graphite is a workhorse in high-temperature sealing applications. It’s used extensively as gasket or packing material in valves that operate in hot environments. Graphite maintains its integrity under heat and pressure better than many polymers, and it offers good chemical resistance.

On the flip side, graphite is brittle and can break under mechanical shock. It also doesn’t seal as tightly as some elastomers, so it’s often used in combination with other materials.

- Ceramic

Ceramic materials bring extreme hardness and outstanding resistance to heat, wear, and corrosion. In specialized valves—like those handling abrasive slurries or ultra-high-temperature gases—ceramic components can significantly extend service life.

The challenges? Ceramics are brittle, difficult to machine, and costly. Even so, for certain tough applications, their performance benefits outweigh the drawbacks.

3.How to Choose the Right Valve Material

Selecting valve materials for a power plant isn’t just about picking the strongest or most resistant option. Engineers must consider:

- Temperature & Pressure Ranges – Will the material maintain strength and seal integrity?

- Corrosive Media – Is the valve exposed to steam, chemicals, or abrasive particles?

- Cycle Life – How often will the valve be operated?

- Cost & Availability – Is the material practical for the project budget and timeline?

Often, valves in power plants use a combination of materials—metal bodies with specialized non-metal internals—to balance performance, durability, and cost.

4.Conclusion

Valve selection in power plants is a careful science. Whether it’s dependable carbon steel, robust alloy steel, corrosion-resistant stainless steel, or premium high-temperature alloys for the most severe conditions—each metal has a role. Likewise, non-metals like PTFE, graphite, and ceramics bring essential sealing and lining solutions to the table.

By understanding the properties, advantages, and limitations of these materials, engineers and buyers can make smarter, safer, and more economical decisions—ensuring that every valve not only fits the system but also stands up to the heat and pressure of real-world operation.

Post time: Oct-17-2025